The filling and closing of a wide variety of objects can only take place under optimal, sterile conditions. To ensure a high level of safety and reliability, the right technical solution and decades of experience are required.

ROTA offers the suitable filling concept for any liquids with high reproducibility and maximum precision.

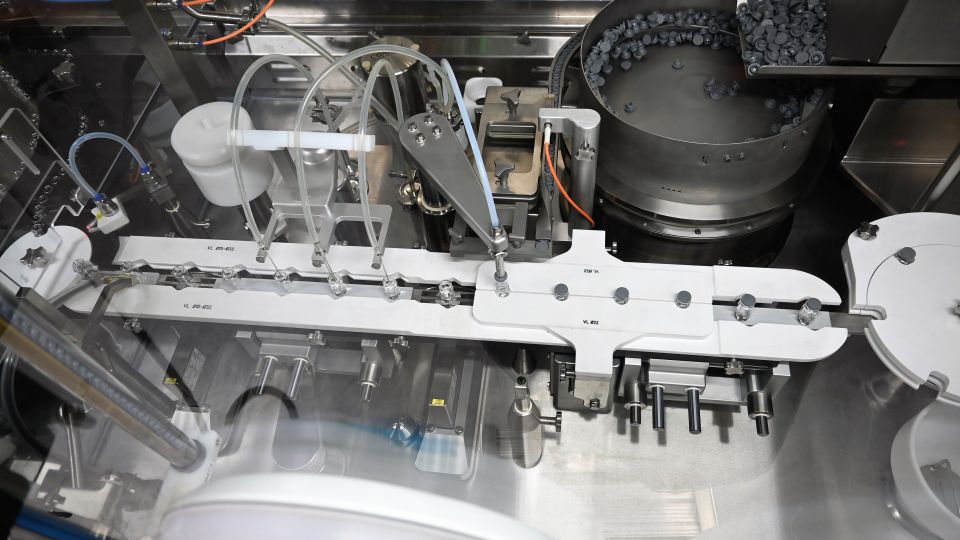

ROTA seal-less rotary piston pumps guarantee high filling accuracy in continuous operation, without readjustment. Easy handling facilitates cleaning and sterilization of the filling system, whether manually or in automatic CIP/SIP processes. Peristaltic pumps are characterized by their flexibility and "single-use" concept.

Ampoules

ROTA is the pioneer in this field with its ampoule filling and closing machines.

The performance range includes machines for small production batches to mass production and are ideal as stand-alone machines or integration into compact high-performance production lines. ROTA machines can process both closed (DIN ISO type D) ampoules, as well as open (type B/spit ampoule or type C/hopper ampoule) ampoules.

A comprehensive range of accessories and special equipment allow the machines to be adapted to individual requirements.

Vials and bottles

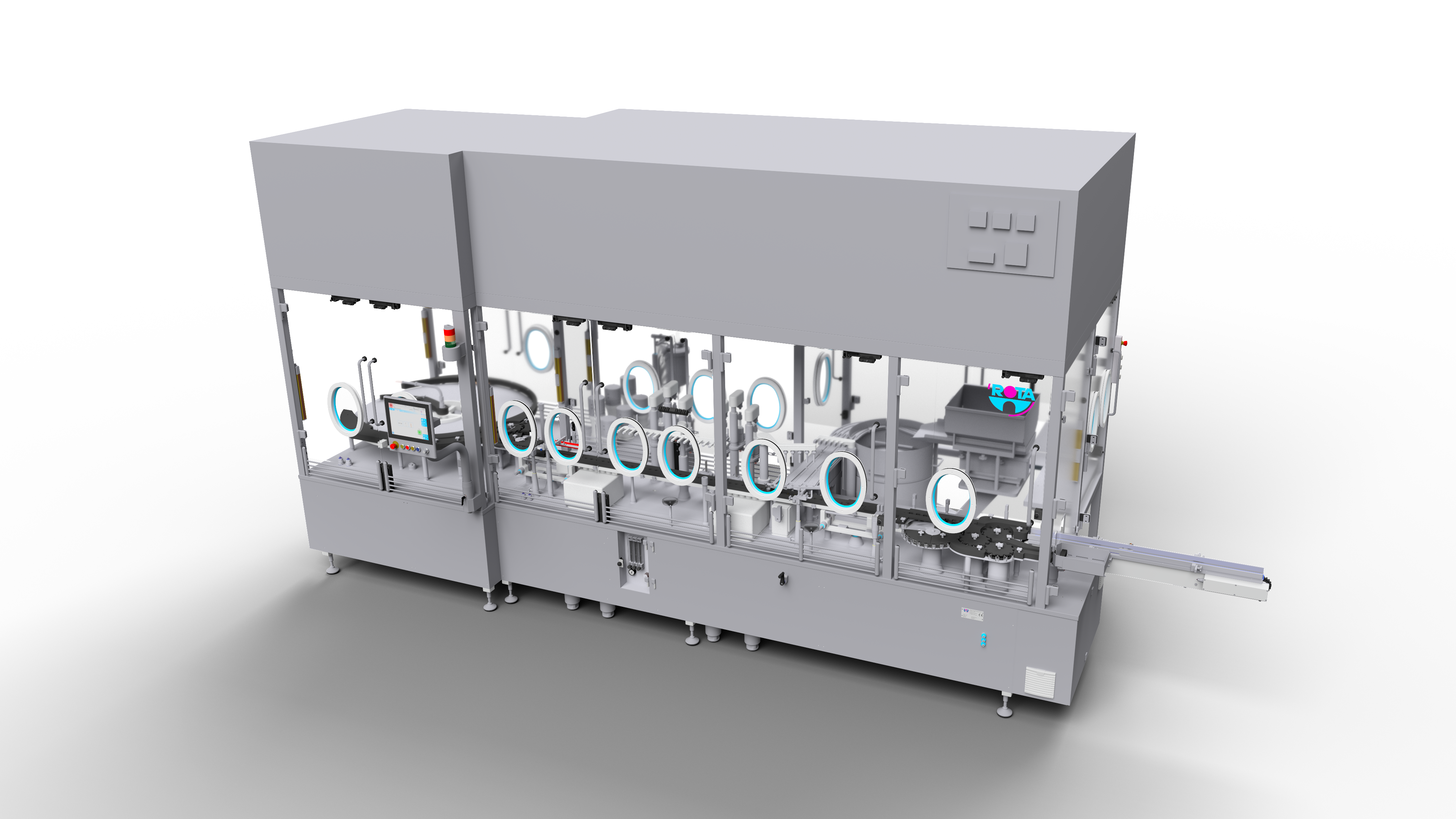

The ROTA filling and closing machines for vials and bottles (closing by means of stoppers) are suitable for filling and closing all free-flowing liquids under sterile or non-sterile conditions. With up to eight filling stations and with one or two closing stations, they are suitable for vials and injection bottles from 2R to 250H. The machines can operate as stand-alone machines or as part of a line.

The use of fully automatic in-process control, whether statistical or 100% at full capacity, ensures continuous testing and documentation.

Combination of ampoules & glass vials

ROTA was one of the first machine manufacturers to offer so-called combination machines in its portfolio. These offer the possibility of filling and closing both ampoules and vials. ROTA combination machines are characterized by fast changeover without dismantling main processing components, thus increasing machine availability and productivity.

All ROTA machines and lines feature state-of-the-art technology and servo drives and a transport system that is as innovative as it is reliable.

Since the processing of vials implies a wide range of bottle types and closure types, the machines are available in many variants. They all offer a wide range of customization options in a remarkably small footprint.

Eye drops & nasal spray

The aseptic processing of eye drop and nasal spray bottles demands special flexibility from the machines.

ROTA filling and capping machines for eye drops and nasal sprays are equipped with up to four filling stations and up to three closing systems such as dropper, screw cap or snap-on cap. Whether small or large bottles made of glass or plastic, with manual feed or automatic feed via, for example, sorting equipment and blow-out (air rinsing) machine, ROTA has the solution.

ROTA offers the best filling concept with rotary piston pumps from its own high-precision production and/or peristaltic pumps, including the possibility of recirculation for suspension products.

The use of fully automatic in-process control, whether statistical or 100% at full capacity, ensures continuous testing and documentation.

Diagnostics & Plastic Bottles

ROTA filling and closing machines for diagnostic and plastic bottles are available with up to four filling stations and up to three closing stations for stoppers/droppers, aluminum caps and screw caps.

When processing small to large bottles made of glass or plastic, diagnostic tubes or injection vials, ROTA covers all common closure types. The objects are fed either manually or fully automatically.

With a choice of ROTA rotary piston pumps and/or peristaltic pumps, ROTA offers a flexible filling concept, including the possibility of recirculation for suspension products. The fully automatic in-process control, whether statistical or 100% at full capacity, ensures continuous testing and documentation.

Nest processing

When processing nested and pre-sterilized objects, ROTA demonstrates its decades of experience as a partner to the pharmaceutical industry. Whether syringes, vials or cartridges: ROTA supplies both machines for manual handling and systems for fully automatic transport of the tubs and nests. Automatic opening systems are used to remove the outer packaging, the cover film and the nonwoven insert.

ROTA machines are characterized by the use of the most modern servo motor technology and the use of the latest generation of machine elements in the smallest footprint. Serial kinematics robotics (SCARA) and advanced control programming enable precise individual processing steps. They achieve automatic, smooth processing while maintaining the highest product quality.

Denesters and machines for labeling and secondary packaging (insertion of piston rods and assembly of back-stops) offer the possibility of obtaining everything from a single source and from the same manufacturer. You benefit from uniform technology, similar intuitive operation, extensive equipment, and the service of experienced experts and engineers.

Technical data

Ampoules

From 0.2 ml to 30 ml

Up to 24,000 per h

Vials and bottles

From 10 µl to 250 ml

Up to 24,000 per h

Combination ampoules & glass bottles

From Ø 9 mm up to Ø 52 mm

Eye drops & nasal spray

Up to 12,000 per h

Diagnostics & plastic bottles

Up to 12,000 per h

Nest processing

Up to 11,500 objects per h

Do you need support?

We are happy to answer any questions you may have.

Just contact us, we look forward to hearing from you!